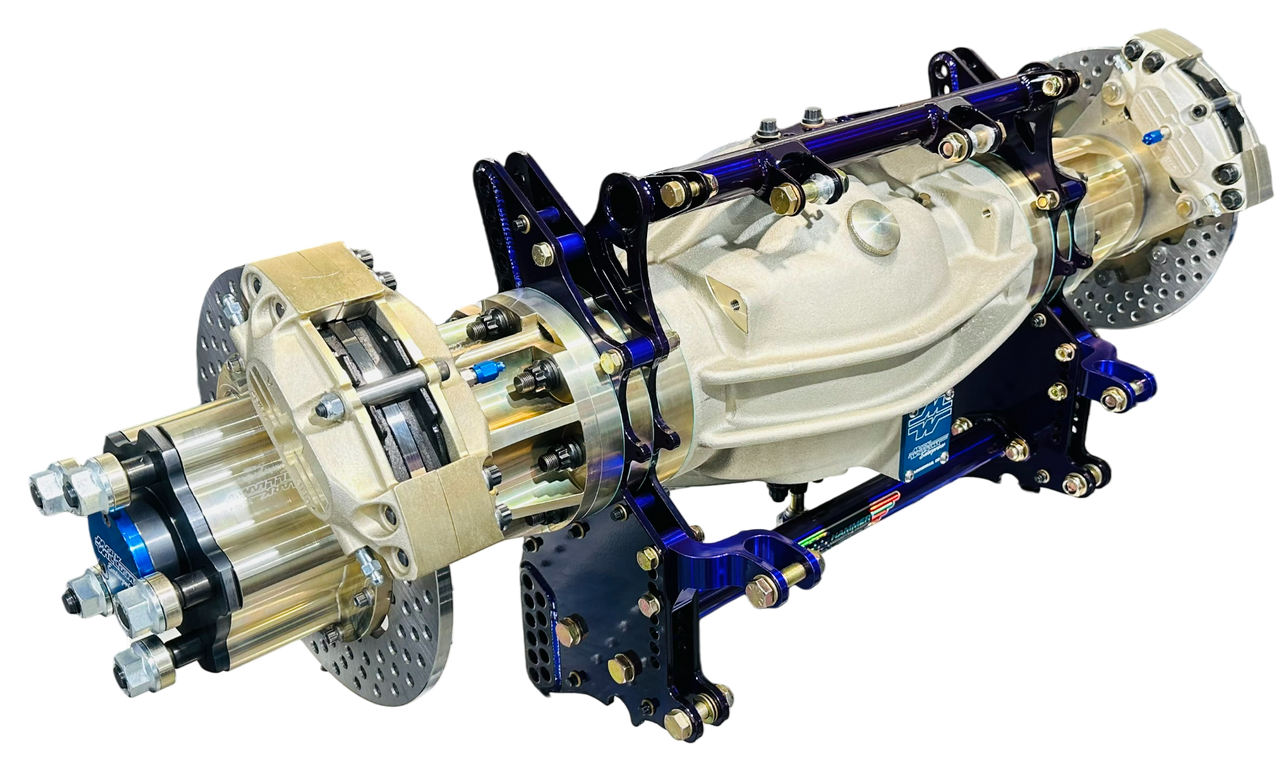

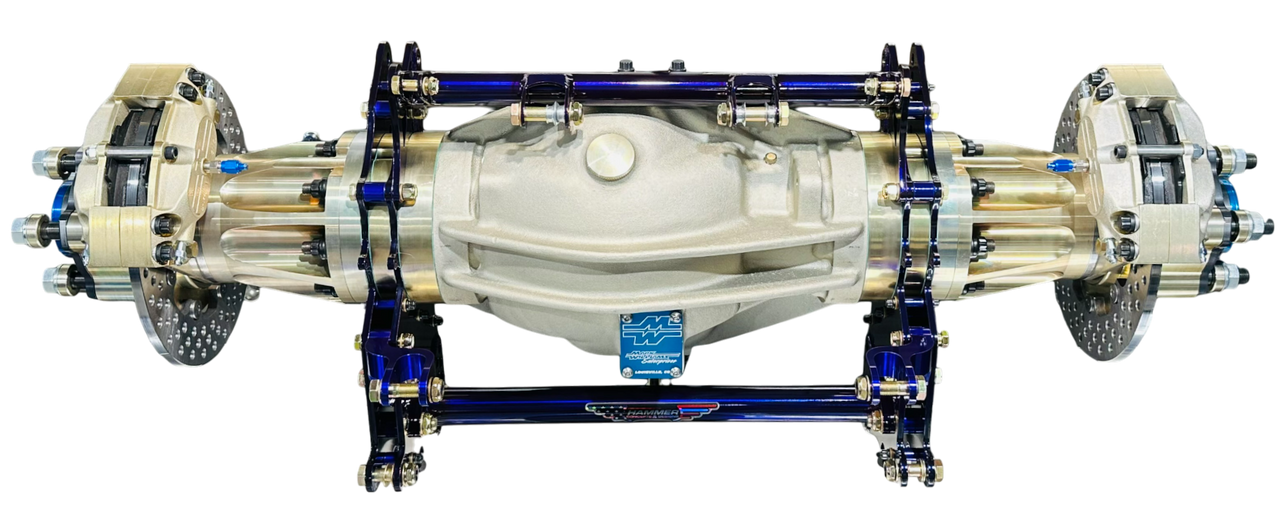

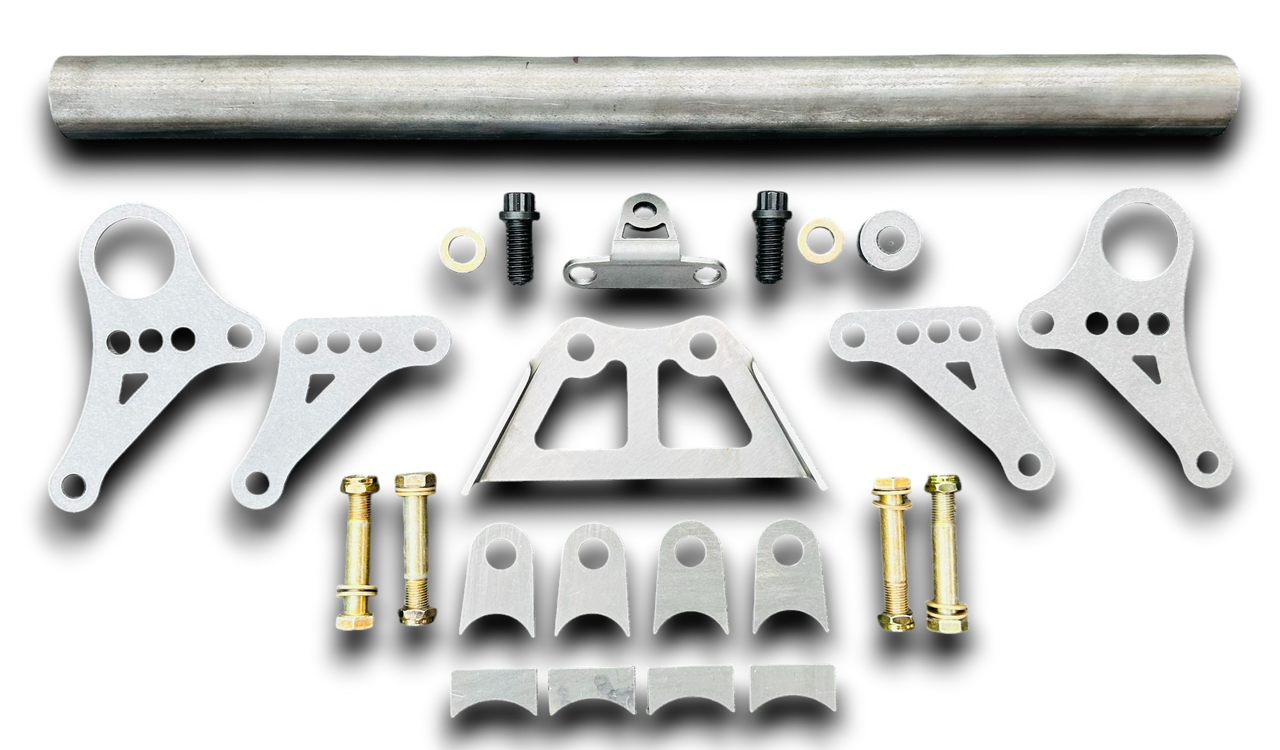

Mark Williams Modular Housings

Get optimum performance and reliability with MW Modular rears. They are stronger, lighter, and more efficient. This technology was created by Mark Williams, and has been refined over the years to remain the best on the market today.

MW modular rears are manufactured from a special high-strength aerospace alloy that has proven to be far more rigid and precise than fabricated steel housings. We can use Ford 9", 9-1/2", and 10".

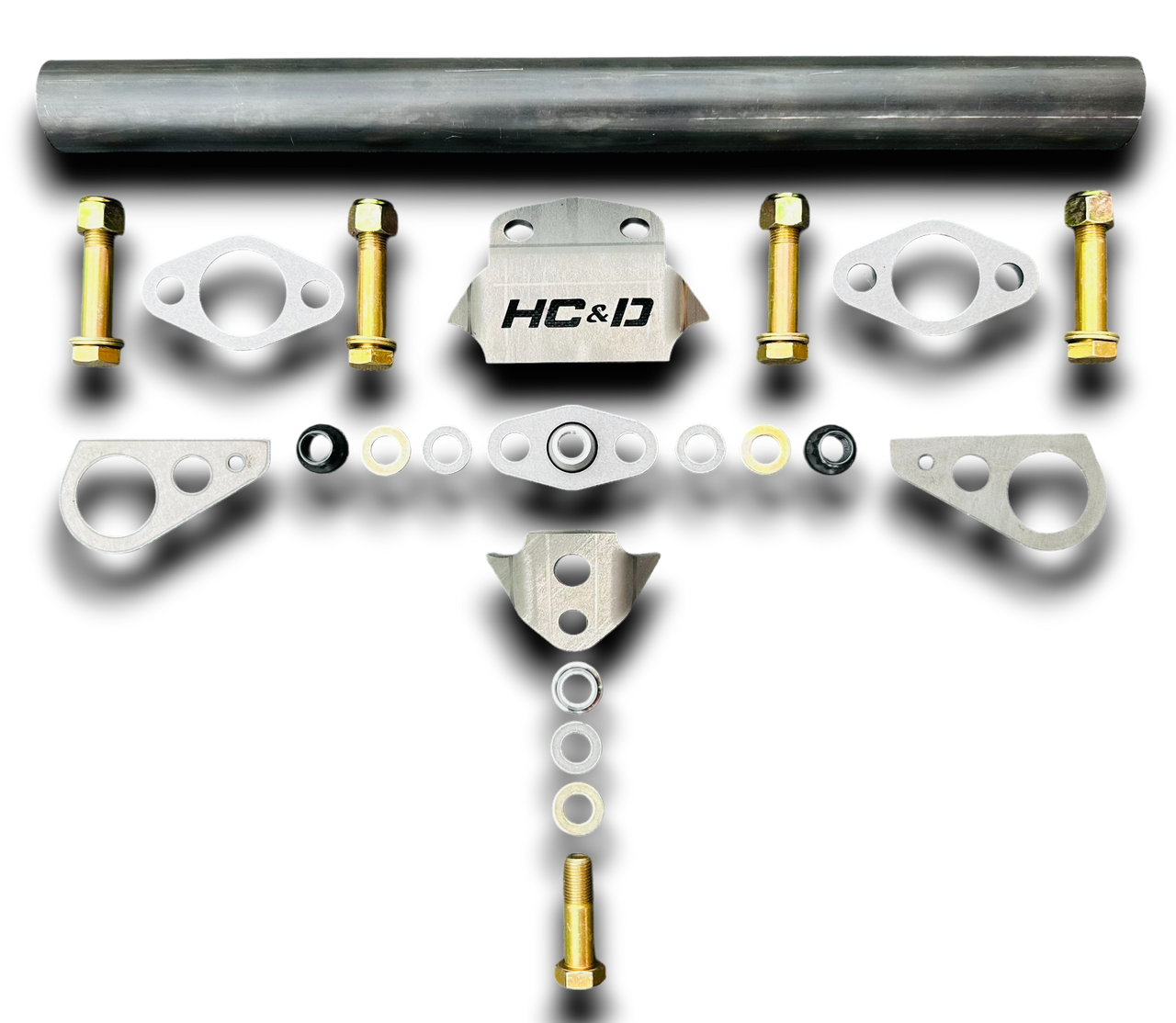

Every racer wants to get better over time, and there is no better way to do it than with a modular rear from MW. The modular design makes it easy to upgrade your current car or swap the unit to a different car if you need to. You can change the housing widths with end bells and spacers. You can change the mount between 4-link and solid-mount, and choose from a coupler or yoke setup for connection to the driveshaft.

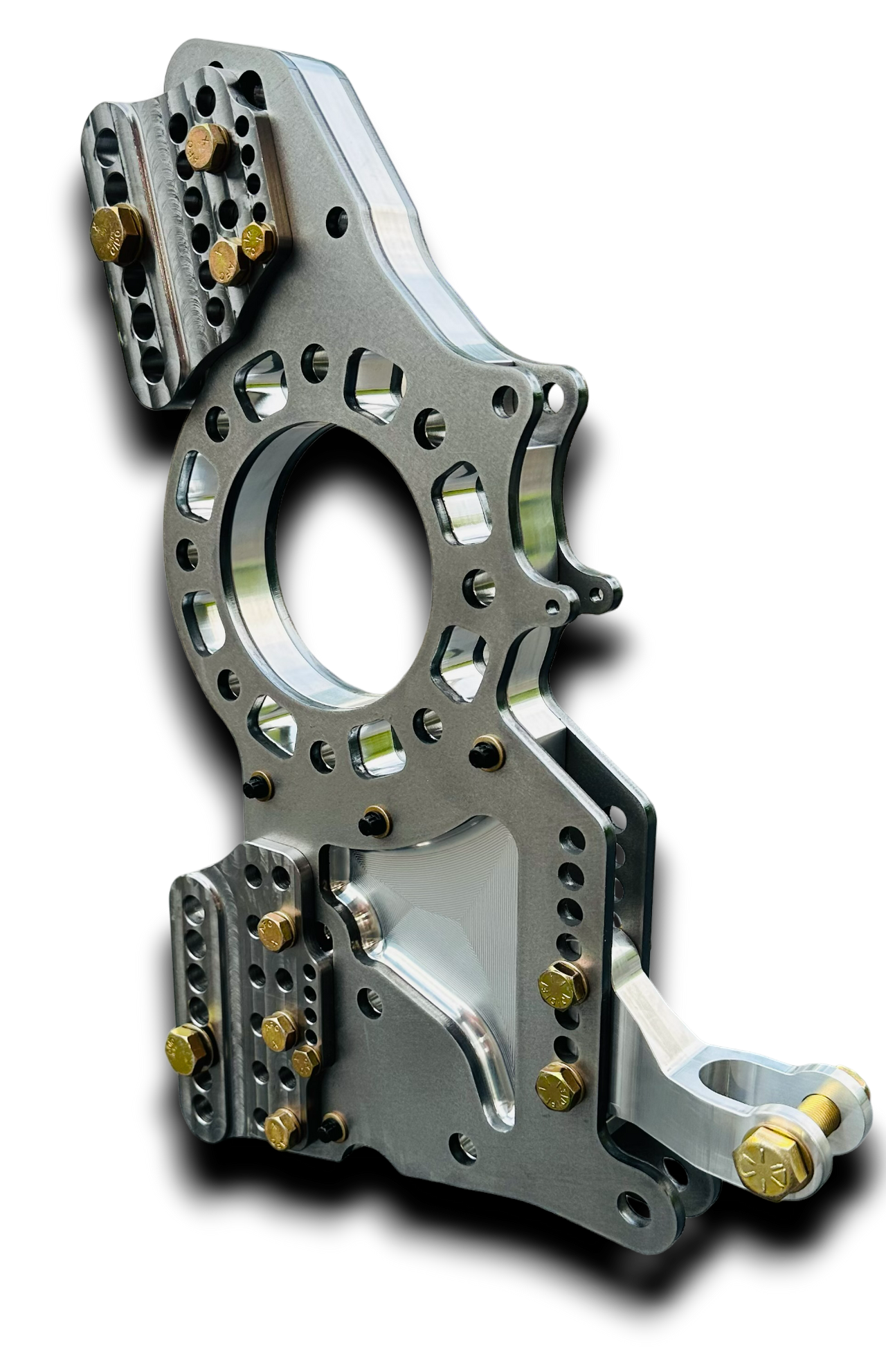

Versatile

With MW's modular housing you can easily change end bells and mounting methods to accommodate a wide variety of applications. Many components are interchangeable so you can upgrade from a 9" (or 9.5") to 10" setup.

Efficient

Because everything is precision CNC machined, component alignment is optimized to eliminate power-robbing friction. Moreover, the housings will not distort under hard acceleration, as is the case with many fabricated units.

Light Weight

In many instances, a modular aluminum rear end housing is lighter than a comparable stamped or fabricated steel unit. This is obviously a performance advantage.

Cost Effective

Not only are MW modular aluminum housings priced competitively with similarly equipped fabricated units, but the improvement in component life will pay big dividends.

Wide Range of Gear Ratios

Variety of ratios available for 9", 9 1/2", 10",MW rears.

Custom Made for YOUR Setup

4 link applications. Flanged or floater axles, steel or carbon brakes, 9", 9.5", and 10" Ford.

Engineered, Tested, & Manufactured In-House

Professionally setup by MW Technicians - Pinion support preload set by experienced staff at MW facility for easy installation in the field, backlash set for maximum gear life, all design work, R&D testing, and manufacturing done in Louisville, CO - USA!